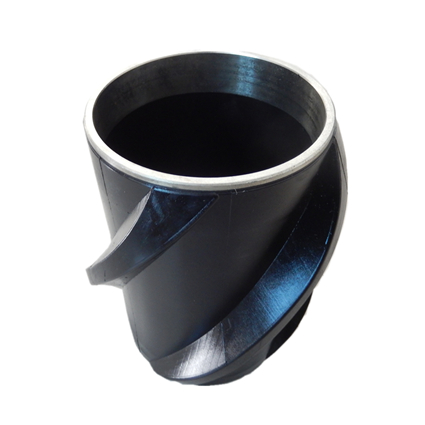

Spiral blade composite centralizer

Spiral blade composite centralizer is recommended to be used in vertical, deviated, horizontal wells, extended-reach wells and wells with high dogleg severity. It is applicable for the wells with temperatures under 350°F (177°C).

The spiral blades enables optimal displacement during primary cementing, which can minimize pressure drop and increase local turbulences across the centralizer.

The composite centralizer is made of one piece of high-quality polymer.

Straight blade composite centralizer

Straight blade composite centralizer has high-impact loading and offers superior wear resistance. It has much better performance than many injection-molded plastic centralizers.

The one piece composite structure make it can withstand high-impact loading and resist wear in high temperatures. And the lightweight construction allows for easier and safer handling when making up casing.

The extra fin length can be concentrated to the greatest extent, and has a higher spacing and increases annular turbulence

Composite centralizer with steel rings

Composite centralizer with steel rings is a kind of composite embedded steel rings in both ends of the centralizer. It is higher hardness and extremely durable, which enables the centralizer to maintain integrity in extreme wellbore temperatures.

-coated-composite-centralizer.jpg)

Teflon (PTFE) coated composite centralizer

Teflon (PTFE) coated composite centralizer is a kind of composite centralizer coated with Teflon (PTFE). It has better heat, wear, corrosion and moisture resistance.

Teflon (PTFE) coated composite centralizer is suitable for many extremely challenging conditions.

The sizes from 4 1/2 to 20 inches sizes are available. We can also provide customized service.

When ordering, please specify:

Hole size or OD of the centralizer

Do you need the steel rings on the two ends of the composite centralizer or not

If impossible, the required length of the centralizer

-composite-roller-casing-centralizer-1.jpg)

-coated-composite-centralizer.jpg)